SwissTech Machinery

Our philosophy, Technology With Commitment, can be defined by one word: SUPPORT. We believe that every Customer should only have to be sold once. Our commitment to supporting each and every Customer like they are our only Customer helps make this a reality. When our Customers need a machine they don’t shop around, they just call us. Don’t believe us? Check out our Customer Testimonials.

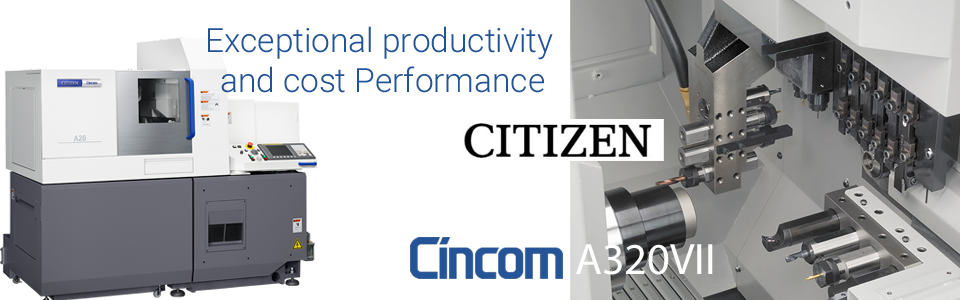

A320VII

Machine Options

Standard Accessories

- Main Spindle Chucking Device

- Back Spindle Chucking Device

- Rotary Guide Bushing Device

- Cut-off tool breakage detection

- Lighting

- Workpiece separator

- Lubricating oil supply unit with

level Detector - Door lock

- Pneumatic device for air sealing

- Machine relocation Detector

Optional Accessories

- Fixed guide bushing device

- Knock-out jig for through-hole workpiece

- Long workpiece unit

- Workpiece conveyor

- Chip Conveyor

- Coolant flow rate Detector

- Signal lamp

- 3-color signal tower

Specifications

Number of axis - 7

Main spindle

- Max. turning diameter - 20mm

- Max. turning length (in one chucking) - 200mm

- Spindle speed - 10,000RPM

- Drive Rating - 3.7kW

- No. of turning tools - 5

- Number of tools for front-end machining - 4

- C-Axis - 0.001°

Sub-spindle

- Max. workpiece diameter - 20mm

- Max. workpiece length - 80mm

- Drive rating - 1.5kW

- Spindle speed - 8,000RPM

- Number of tools for back-end machining - 8

- C-Axis - 0.001°

Driven Tools

- No. of Driven Tools (transverse) - 4

- Driven Tool Motor Power - 0.75kW

- Driven Tool Max. Speed - 6,000RPM

Other Information

- Axis rapid Traverse - 32m/min

- Space Requirement - 2100x1185mm

- Weight - 4,851

Machine Overview

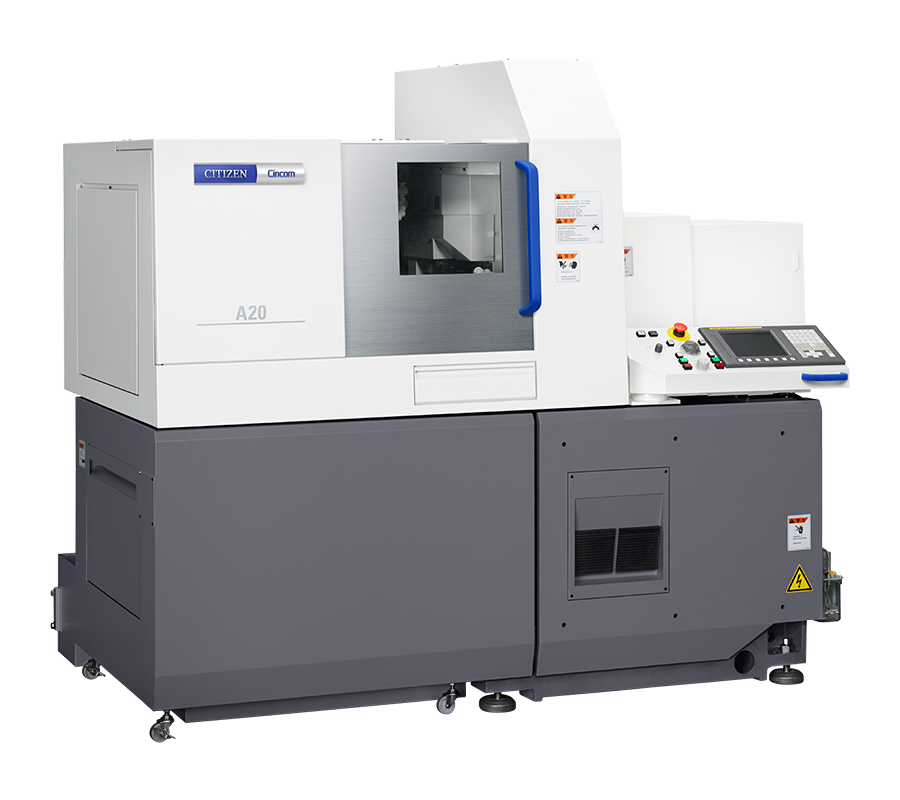

Acclaimed for its excellent cost to performance ratio, the A20 has evolved as a 5-axis machine for ø20 mm applications with the advantage that it can be used with or without a guide bushing. Use as a regular guide bushing automatic lathe when machining long, slender workpieces or without a guide bushing for shorter parts with minimal bar end remnants. The guide bushing can be quickly and easily mounted or removed.

The performance of the machine has been improved too. The high speed 10,000 rpm spindle enables optimized machining operations on smaller diameter bar material. The machining length per chucking is now extended to 200 mm enabling the number of re-chuckings and therefore cycle times to be reduced when machining long workpieces. As an option, bar material of up to ø25 mm can also be machined extending the range of workpieces.

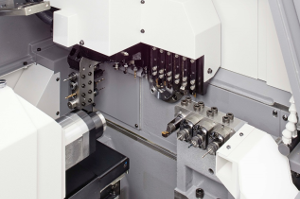

Work Area

Vertical Tool Holder

- 4 rotary cross-drilling / milling spindles and 5 turning tools fitted as standard for turning, grooving, screw-cutting, parting-off etc.

- One cross tool can be replaced with one of:

- BSE607: 3 front live end face

- Front: F7 - M5 (ER11).

- BSE707: 3 front / 3 back live end face

- Front: F7 - M5 (ER11)

- Back: F5 - M4 (ER11)

- BSE607: 3 front live end face

End Working Holder 1

- 4 stations for front machining

- 4 stations for back machining

End Working Holder 2

- 4 fixed stations for back machining. With A220-U151B option, all 4 can be utilized for either live or fixed end working (4,500RPM / 0.75kW).

- Optional GSS1330 Back Slitting and Cross-Drilling

Spindle:

- ER11, 3600RPM, 3/5 Gear Ratio

- Adjustable 90° for cross-drilling

L220X

Machine Options

Standard Accessories

- Main Spindle Chucking Device

- Back Spindle chucking device

- Headstock Cooling Device

- Door Switch

- Lubricating Oil Supply

- Pneumatic Device for air sealing

- Part-off Tool Breakage Detector(Electronic type)

- Work Area Lamp

- Cutting oil level detection

Optional Accessories

- Extensive toolholder options

- Choice of Barfeeder

- Coolblaster High Pressure Coolant

- Mist Control

- Long Parts Adapter

- Chip Conveyor

- Part-off Tool Breakage Detector(Probe type)

Specifications

Main spindle - AC motor

- Bar Capacity - 20mm up to 25mm (.984) with option

- Max. Turning Len. (no rechucking) - 200mm

- Motor Rating - 2.2/3.7kW

- Spindle speed range - 200-10,000RPM

- C-axis - 0.001°

Sub-spindle - AC motor

- Maximum workpiece diameter - 20mm up to 25mm (.984) with option

- Motor Rating - 0.75 / 1.5kW

- Spindle speed range - 200-8,000RPM

- Spindle Indexing - 1°

- C-axis - 0.001°

Tools

- Number of turning tools - 5

- Number of drilling/boring tools-front - 6(14)

- Number of back operation tools - 8(16)

- Number of rotary tools-cross - 5(14)

- Number of rotary tool positions face - 5(21)

- Rotary tool power - 1kW

- Rotary tool speed range - 200-6,000RPM

Machine Overview

The L220X offers increased tool flexibility with up to 44 tools capability featuring 2 Y-axis.

The back working tool post utilizes Y-axis for up to 8 fixed or rotary, end-face or cross working tool holders for increased overlapping machining capability.

Another major feature is the ability to switch between guide bushing and guide bushing-less type. This feature is provided as standard; the guide bushing can be fitted or removed very quickly with a simple operation.

The user-friendly editing function which utilizes multi line, multi axis programming, along with superimosed and synchronized control make setting up the most complex jobs easy.

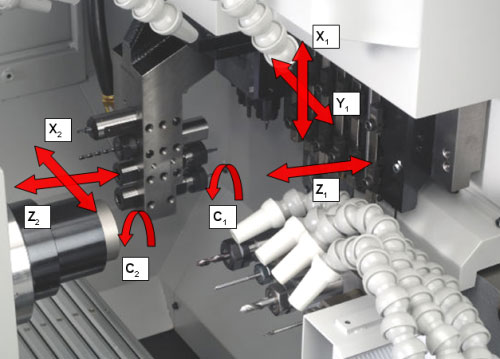

Work Area

Vertical Holder

- 7 rotary spindles (3 can be swiveled 90 deg. between cross and end facing machining) and 5 turning tools fitted as standard for turning, grooving, screw-cutting, parting-off etc.

- Standard Y-axis facilitates tool center height adjustment and enables complex operations to be carried out with ease.

- Rotary tools rated at 1kW / 6,000RPM.

- Tooling arrangements allow extra cross rotary tools, extra turning tools or extra end-working rotary tools depending on your priorities.

Front / Back Machining Holders

- Front Machining Post

- 6 front working positions as standard (up to 3 rotary tools, 0.75kW/7,500RPM)

- Y-axis as standard to enable simultaneous control of gang and front machining post.

- Allows operations such as drilling, tapping, screw-cutting, boring and turining to be carried out simultaneously with other operations.

- Back Machining Post

- 4 fixed/4 rotary back-working positions with 2 rotary

GSE3507 as standard.

- Allows operations such as drilling, tapping, screw-cutting, boring and turning to be carried out simultaneously with other operations.

- 4 fixed/4 rotary back-working positions with 2 rotary

GSE3507 as standard.

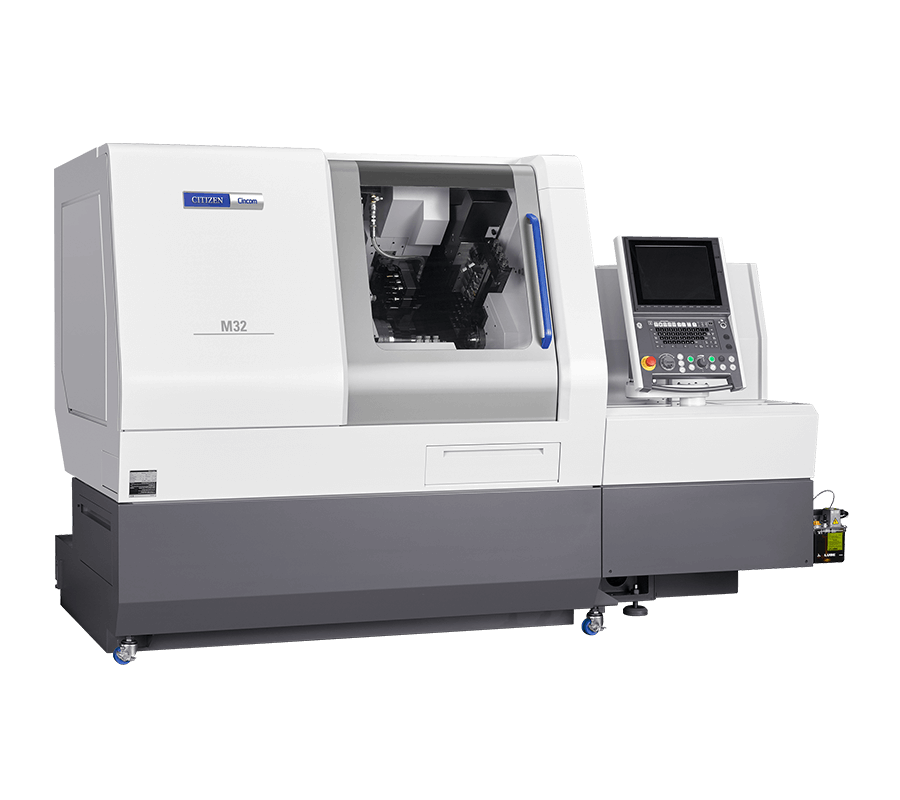

M532VIII

Machine Options

Standard Accessories

- Main Spindle Chucking Device

- Back Spindle Chucking Device

- Headstock Cooling Device

- Door Switch

- Lubricating Oil Supply

- Pneumatic Device for air sealing

- Part-off Tool Breakage Detector(Electronic type)

- Work Area Lamp

- Cutting oil level detection

Optional Accessories

- Extensive toolholder options

- Choice of Barfeeder

- Coolblaster High Pressure Coolant

- Mist Control Unit

- Long Parts Adapter

- Chip Conveyor

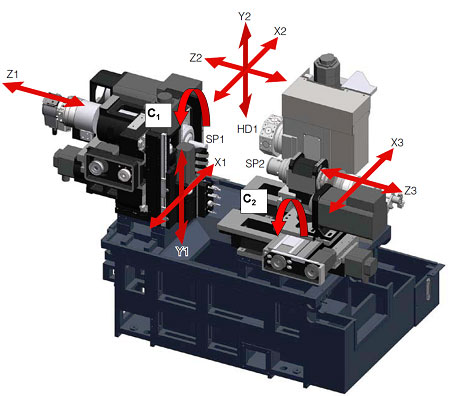

Specifications

Main spindle

- • Max. turning diameter - 32mm (38mm Option)

- Max. turning length - 320mm

- Main spindle speed - 200-8,000RPM

- Main spindle drive power - 5.5 / 7.5kW

- C-Axis - 0.001°

Sub-spindle

- • Max. workpiece diameter - 32mm (38mm Option)

- Motor rating - 5.5 / 7.5kW

- Sub-spindle speed - 200-8,000RPM

- C-Axis - 0.001°

Vertical Tool Post

- Turning tools in vertical tool holder platen - 5

- Number of rotary tools - 8

- Driven Tool Power - 2.2kW

- Speed of tools - 200-9,000RPM

Opposed Tool Post

- Fixed tools for back machining - 3

- Driven tools for back machining - up to 6

- Y Axis - Yes

Turret

- Y-Axis - Yes

- Driven stations on turret - 10

- Max. number of tools - 36+

- Driven tool power - 1.5 / 2.2kW

- Speed of driven tools - 200-6,000RPM

Other Information

- Space requirement (without bar feeder) - 2,860 x 1,465 x 1,900mm

- Weight - 4,300kg

Machine Overview

More tools!... more functions!... more flexibility!...higher productivity!... same floor space!

Even greater value!

The M32 is renowned for its leading capability for 3 tool simultaneous machining in a compact floor space. The all round combination of flexible tooling, large tool capacity, and outstanding ease of use has made the M32 our success story in the new century. The next generation M32 increases the 3 tool simultaneous machining abilities with a Y3 axis on the back tool post which carries up to 9 tools (up to 6 driven). In addition, the machine boasts an improved / upgraded turret with adoption of single drive for rotary toolholders, fast rapid feed rate (up to 32m/min) and reduced power consumption

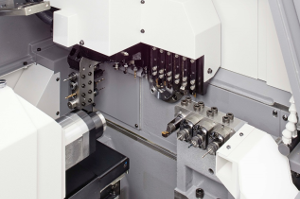

Work Area

Vertical Holder

- 8 rotary cross-drilling / milling spindles and 5 turning tools for turning, grooving, screw-cutting, parting-off etc.

- Standard Y-axis facilitates tool center height adjustment and enables complex operations to be carried out with ease.

Turret

- Allows Front and back machining including pinch milling.

- High-torque power driven tools available for all 10 stations (6,000RPM and 2.2kW).

- Multiple tool holders and intermediate indexing allow 36+ tools to be fitted.

- Tools can be indexed directly without turret retraction saving 0.5 secs per index.

- Y-Axis allows tool change without turret indexing and tool offset adjustment in 3 axes.

- Double / Triple sleeve tool holder and double cross-spindle take full advantage of Y-axis.

Back working Tool Post

- Can accommodate holders at 3 positions (2 for rotary tool specifications – 1kW / 6000rpm and 1 for fixed tool specifications)

- • Up to 9 tools can be fitted.

L12VII

Machine Options

Standard Accessories

- Main Spindle Chucking Device

- Back Spindle chucking device

- Headstock Cooling Device

- Door Switch

- Lubricating Oil Supply

- Pneumatic Device for air sealing

- Medium Pressure Coolant Supply Unit

- Part-off Tool Breakage Detector(Electronic type)

- Work Area Lamp

- Cutting oil level detection

Optional Accessories

- Extensive toolholder options

- Choice of Barfeeder

- Coolblaster High Pressure Coolant

- Mist Control Unit

- Long Parts Adapter

- Chip Conveyor

- Part-off Tool Breakage Detector(Probe type)

Specifications

Main spindle - AC motor

- Bar Capacity - 12mm

- Motor Rating - 2.2 / 3.7kW

- Spindle speed - 15,000

- No. of fixed tools for front-end machining - 4

- No. of cross rotary tools - 4

- Rotary tool power - 0.75kW

- Rotary tool speed - 10,000RPM

- No. of turning tools - 6

- C-axis - 0.001°

Sub-spindle - AC motor

- Maximum workpiece diameter - 12mm

- Motor Rating - 0.4 / 0.75kW

- Spindle speed - 10,000RPM

- No. of tools for back-end machining - 4 (8)

- No. of driven tools for back-end machining - 4

- Rotary tool power - 0.75kW

- Rotary tool speed - 9,000RPM

- C-axis - 0.001°

Machine Overview

The new L12-VII, including Switchable Guide Bush System allows the ‘best of both worlds’ for efficient machining of both long and short workpieces

Flexible tooling options available including fixed and rotary tools for front \ back-machining as well as 0-30° adjustable angle rotary tool post.

High speed 15,000RPM main spindle with 3.7kW motor - sub spindle 10,000RPM \ 0.75kW.

Work Area

Vertical Holder

- Vertical holder with 6 turning tools

- Gang rotary tools:

- ER11 10mm offset 2 stations

- ER8 5mm offset 1 station

- 10,000RPM 0.75kW

Front / back machining holder

- Fixed 8 position (4 front / 4 back drilling holder)

- 0-30° adjustable angle 6 position (3 front / 3 back) rotary tool post.

- 10000RPM 0.75kW drive

Back Working Holder

- 4 fixed / rotary spindles for back machining

- Rotary tools drive 9,000RPM / 0.5kW

- Allows operations such as drilling, tapping, screw-cutting, boring and turning to be carried out simultaneously with other operations.

- ER11

L220X

Machine Options

Standard Accessories

- Main Spindle Chucking Device

- Back Spindle chucking device

- Door Switch

- Lubricating Oil Supply

- Pneumatic Device for air sealing

- Part-off Tool Breakage Detector(Electronic type)

- Work Area Lamp

- Cutting oil level detection

Optional Accessories

- Extensive toolholder options

- Choice of Barfeeder

- Coolblaster High Pressure Coolant

- Mist Control Unit

- Long Parts Adapter

- Chip Conveyor

- Part-off Tool Breakage Detector(Probe type)

Specifications

Main spindle - AC motor

- Bar Capacity - 20mm up to 25mm (.984) with option

- Max. Turning Length (no rechucking) - 200mm

- Motor Rating - 2.2/3.7kW

- Spindle speed range - 200-10,000RPM

- C-axis - 0.001°

Sub-spindle - AC motor

- Maximum workpiece diameter - 20mm (.984) with option

- Motor Rating - 0.75/1.5kW

- Spindle speed range - 200-8,000RPM

- Spindle Indexing - 1°

- C-axis - 0.001°

Tools

- Number of turning tools - 5

- Number of drilling / boring tools - front - 6(14)

- Number of back operation tools - 8(16)

- Number of rotary tools - cross - 5(14)

- Number of rotary tool positions cross/front face - 3/3 (5/21)

- Rotary tool power - 1kW

- Rotary tool speed range - 200-5,000RPM

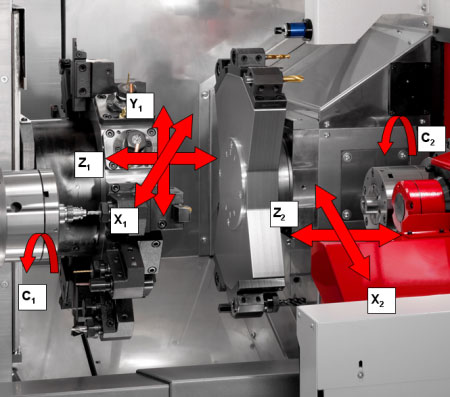

The Cincom L220X offers increased tool flexibilty with up to 44 tools capability featuring two Y-axis.

The back working tool post utilizes Y-axis for up to 8 fixed or rotary, end face or cross working tool holders for increased overlapping machining capability.

Another major feature is the ability to switch between guide bushing and guide bushing-less type. This feature is provided as standard; the guide bushing can be fitted or removed very quickly with a simple operation.

The user-friendly editing function which utilizes multi line, multi axes programming, along with superimposed and synchronized control make setting up the most complex jobs easy.

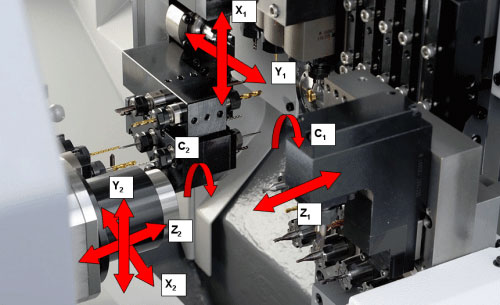

Work Area

Vertical Holder

- 7 rotary spindles ( 3 can be swiveled 90 deg between cross and end face machining) and 5 turning tools fitted as standard for turning, grooving, screw-cutting, parting-off etc.

- Standard Y-axis facilitates tool center height adjustment and enables complex operations to be carried out with ease.

- Rotary tools rated at 1kW / 6,000RPM.

- Tooling arrangements allow extra cross rotary tools, extra turning tools or extra end-working rotary tools depending on your priorities.

Front / Back Machining Holders

- 6 fixed end-working positions (3 front / 4 back) as standard (8 optional 3 front / 5 back).

- Allows operations such as drilling, tapping, screw-cutting, boring and turning to be carried out simulataneously with other operations.

- Optionally sub spindle opposed toolpost can be fitted with up to 4 rotary tools (0.4kW, 5,000RPM).

BNA-42GTY

Machine Options

Standard Accessories

- Comprehensive static toolholder package

- Auto Power Shut-off

- Cut-off Confirmation

- Parts Catcher

- Chip conveyor

- Parts Conveyor

- Medium Pressure Coolant system

Optional Accessories

- Automatic bar feeder

- Mist Control Unit

- In cycle probing

- Work handling automation

- 1,000 PSI High Pressure Coolant

Specifications

Main Spindle

- Bar Capacity - 42mm

- Standard Machining length - 110mm

- Motor - 11 / 7.5kW

- Spindle speed range - 50~6,000RPM

- C-axis - 0.001°

Sub Spindle

- Maximum workpiece diameter - 42mm

- Motor - 5.5/3.7kW

- Spindle speed range - 50~5,000RPM

- C-axis - 0.001°

Turret Head

- Number of Turrets - 1

- Number of Stations - 8 (16)

- Number of Driven tools - 8

- Drive motor of Driven tool. - 8 ( 2.8/1.0kW )Nm

- Driven tool speed range - Max. 6,000RPM

Gang Tool Slide

- Turning Tools - 3

- Number of Cross Rotary Tools - 3

- Fixed rear facing tools - 7

- Drive motor of Driven tool. - 1.5kW

- Driven tool speed range - Max. 6,000RPM

Dimensions

- Foot print (length width) - 2,350x1,475mm

Machine Overview

Featuring 2 spindles, Y-axis equipped turret and flexible gang toolslide, the BNA-42GTY offers excellent value with independent machining on the front and back of the workpiece simultaneously.

Work Area

Main Spindle

- 42mm Dia.

- 7.5 / 11kW

- 6,000 RPM

- C-Axis

Sub Spindle

- 42mm Dia.

- 3.7 / 5.5kW

- 5,000 RPM

- C-Axis

Turret

- 8 station turret with the half-position indexing mechanism utilizes all 16 turret stations with no turret tool holder interference.

- The 8 driven tool positions are individually powered (2.8 / 1.0kW, 6000rpm) to minimize torque loss and a lubricating system protects the gears inside the turret.

- Featuring Y axis to enable maximum machining flexibility.

- A flexible package of fixed and driven tooling is available.

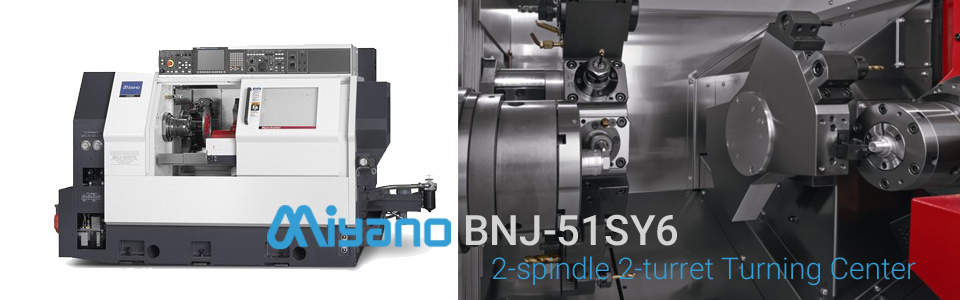

BNJ-51SY6

Machine Options

Standard Accessories

- Comprehensive static toolholder package

- Electronic Handwheel Handle retrace

- Thermo Revision (Stealth System)

- Tool Monitoring System

- Auto Power Shut-off

- Cut-off Confirmation

- Parts Catcher

- Parts Conveyor

- Chip conveyor

- Medium Pressure Coolant system

- Spindle Medium Pressure Coolant

- Spindle Air Blow

- Spindle brake for milling

Optional Accessories

- Automatic bar feeder

- Coolant mist extraction system

- In cycle probing

- Work handling automation

- Long shaft working system

Specifications

Main Spindle

- Bar Capacity - 51mm

- Standard Machining length - 100mm

- Spindle Nose - A2-6

- Motor - 11 /7.5 kW

- Spindle speed range - 50 - 5,000RPM

- C-axis - 0.001°

Sub Spindle

- Maximum workpiece diameter - 42mm

- Spindle Nose - Flat

- Motor - 5.5 /3.7 kW

- Spindle speed range - 67 - 5,000RPM

- C-axis - 0.001°

Turret Head

- Number of Turrets - 2

- Number of Stations - 12 + 6

- Number of Driven tools - 12

- Drive motor of Driven tool. - 20 Nm [ 2.5 kW ]

- Driven tool speed range - 6,000RPM

Machine Overview

Work Area

Main Spindle

- 51mm Dia.

- 11 / 7.5kW

- 5,000 RPM

- A2-6

- C-Axis

Sub Spindle

- 42mm Dia.

- 5.5 / 3.7kW

- 5,000 RPM

- C-Axis

Main Turret

- 12 station turret.

- The 12 driven tool positions are individually powered (2.5kW, 6000rpm) to minimize torque loss.

- A flexible package of fixed and driven tooling is available.

- Y axis as standard allows more complex parts with driven tools.

Sub Turret

- 6 station turret for back working.

- Allows work to be carried out simultaneously on sub spindle whilst main turret works in main spindle.

- Solid construction with no axis movement.

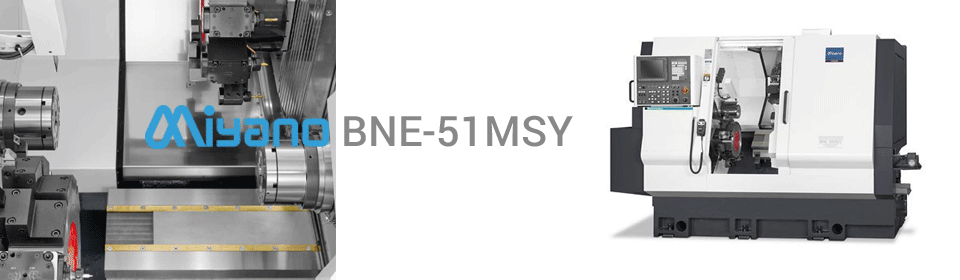

BNE-51MSY

Machine Options

Standard Accessories

- Comprehensive static toolholder package

- Electronic Handwheel Handle retrace

- Tool Monitoring System

- Auto Power Shut-off

- Cut-off Confirmation

- Parts Catcher

- Parts Conveyor

- Chip conveyor

- Medium Pressure Coolant system

- Spindle Medium Pressure Coolant

- Spindle Air Blow

- Spindle brake for milling

Optional Accessories

- Automatic bar feeder

- Mist Control Unit

- In cycle probing

- Work handling automation

- Hainbuch workholding options

- Long shaft working system

Specifications

Main Spindle ( AC motor )

- Bar Capacity - 51mm

- Standard Machining length - 90mm

- Spindle Nose - Flat

- Motor - 15 / 11kW

- Spindle speed range - 50 - 5,000RPM

- C-axis - 0.001°

Sub Spindle ( AC motor )

- Maximum workpiece diameter - 51mm

- Spindle Nose - Flat

- Motor - 7.5 / 5.5kW

- Spindle speed range - 50 - 5,000RPM

- C-axis - 0.001°

Turret Head

- Number of Turrets - 2

- Number of Stations - 24 ( 12 x 2 HEAD )

- Number of Driven tools - 24

- Drive motor of Driven tool - 25 Nm [ 2.2kW ]

- Driven tool speed range - 6,000RPM

- Shank height of Square turning tool - 20mm X 20mm

Work Area

Main Spindle

- 51mm Dia.

- 15 / 11kW

- 5,000 RPM

- Flat

- C-Axis

Sub Spindle

- 51mm Dia.

- 7.5 / 5.5kW

- 5,000 RPM

- Flat

- C-Axis

Twin Turrets

- 2 x 12 station turrets.

- The 12 driven tool positions are individually powered (2.2kW, 6000rpm) to minimize torque loss.

- A flexible package of fixed and driven tooling is available.

- Y axis as standard on upper turret allows more complex parts with driven tools.

- X2 axis on SP2

08 Series

Fast, compact milling centers for high precision and diverse applications.

Technology

- Travel X-Y-Z - up to 450-270-310mm

- Spindle Power - up to 14kW

- Spindle Speed - up to 40,000rmp

- Axis acceleration - up to 2g

- Chip-to-chip time - approx. 1.3s

- Number of tools - max. 225

- Tool taper - HSK 32/HSK 40

L12VII

Machine Options

Standard Accessories

- Main Spindle Chucking Device

- Back Spindle chucking device

- Headstock Cooling Device

- Door Switch

- Lubricating Oil Supply

- Pneumatic Device for air sealing

- Medium Pressure Coolant Supply Unit

- Part-off Tool Breakage Detector(Electronic type)

- Work Area Lamp

- Cutting oil level detection

Optional Accessories

- Extensive toolholder options

- Choice of Barfeeder

- Coolblaster High Pressure Coolant

- Mist Control Unit

- Long Parts Adapter

- Chip Conveyor

- Part-off Tool Breakage Detector(Probe type)

Specifications

Main spindle - AC motor

- Bar Capacity - 12mm

- Motor Rating - 2.2 / 3.7kW

- Spindle speed - 15,000

- No. of fixed tools for front-end machining - 4

- No. of cross rotary tools - 4

- Rotary tool power - 0.75kW

- Rotary tool speed - 10,000RPM

- No. of turning tools - 6

- C-axis - 0.001°

Sub-spindle - AC motor

- Maximum workpiece diameter - 12mm

- Motor Rating - 0.4 / 0.75kW

- Spindle speed - 10,000RPM

- No. of tools for back-end machining - 4 (8)

- No. of driven tools for back-end machining - 4

- Rotary tool power - 0.75kW

- Rotary tool speed - 9,000RPM

- C-axis - 0.001°

Machine Overview

The new L12-VII, including Switchable Guide Bush System allows the ‘best of both worlds’ for efficient machining of both long and short workpieces

Flexible tooling options available including fixed and rotary tools for front \ back-machining as well as 0-30° adjustable angle rotary tool post.

High speed 15,000RPM main spindle with 3.7kW motor - sub spindle 10,000RPM \ 0.75kW.

Work Area

Vertical Holder

- Vertical holder with 6 turning tools

- Gang rotary tools:

- ER11 10mm offset 2 stations

- ER8 5mm offset 1 station

- 10,000RPM 0.75kW

Front / back machining holder

- Fixed 8 position (4 front / 4 back drilling holder)

- 0-30° adjustable angle 6 position (3 front / 3 back) rotary tool post.

- 10000RPM 0.75kW drive

Back Working Holder

- 4 fixed / rotary spindles for back machining

- Rotary tools drive 9,000RPM / 0.5kW

- Allows operations such as drilling, tapping, screw-cutting, boring and turning to be carried out simultaneously with other operations.

- ER11